The Vantec Tornado 92 mm fan was one of the most powerful fans used by computer hardware enthusiasts during the “Pentium 4 era”, in the early 2000’s. It draws 1 A at 12V spinning at 4800 RPM with a noise level of 55 dBA. I bought one, alongside a Thermalright heat sink, and used both for a short time in my personal computer. The fan turned out to be amazingly loud, even when operating at lower voltages. Sure, the CPU temperatures were reduced, but that had no noticeable impact on the performance of my computer, as cooling wasn’t the limiting factor for my overclock. Anyway, after a while I gave up using this cooler on my main rig, and then it sat unused for years.

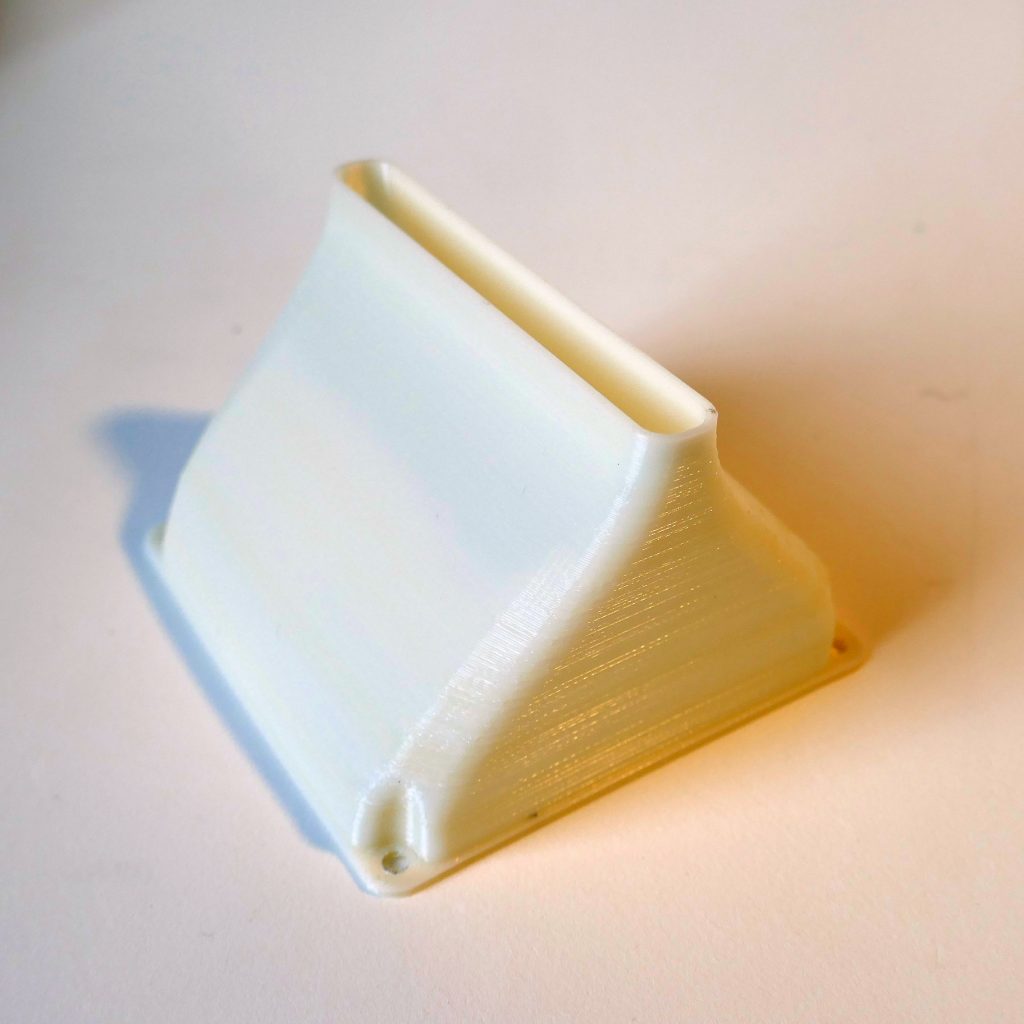

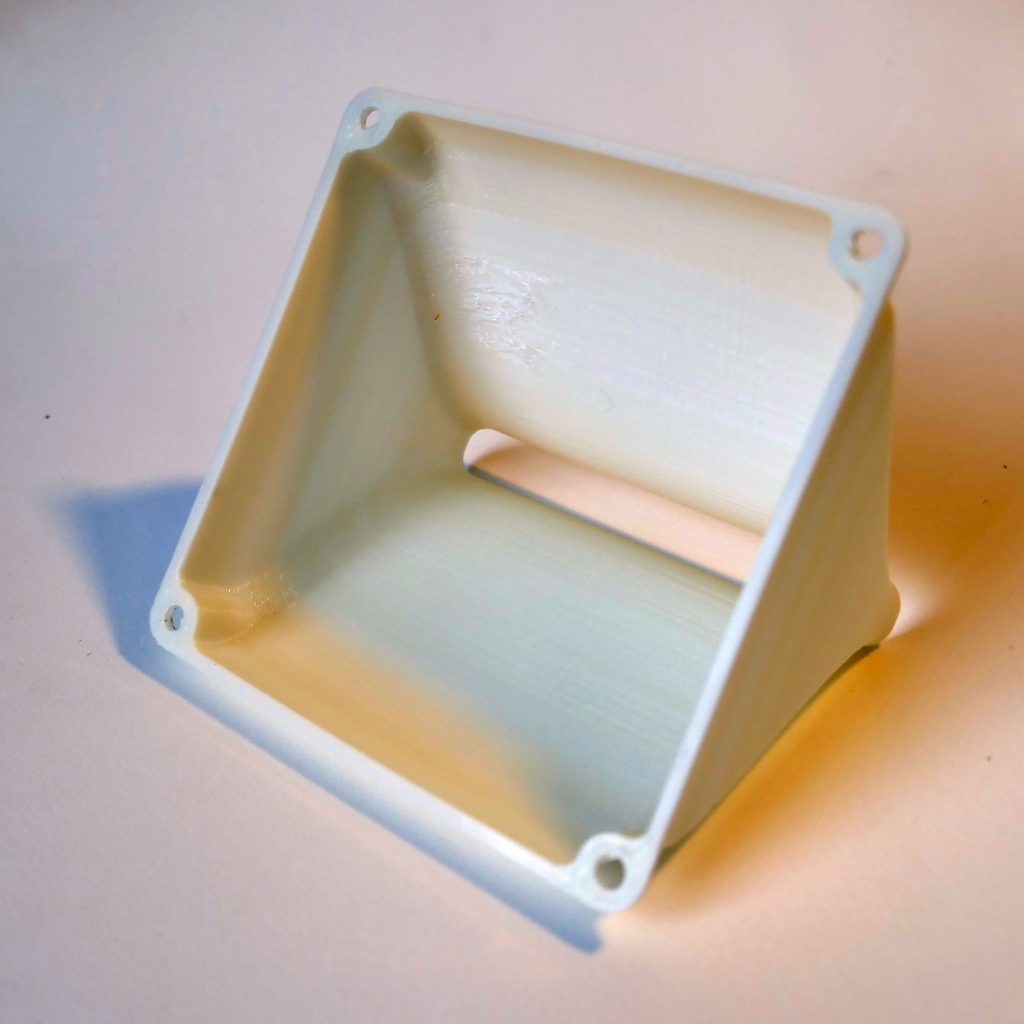

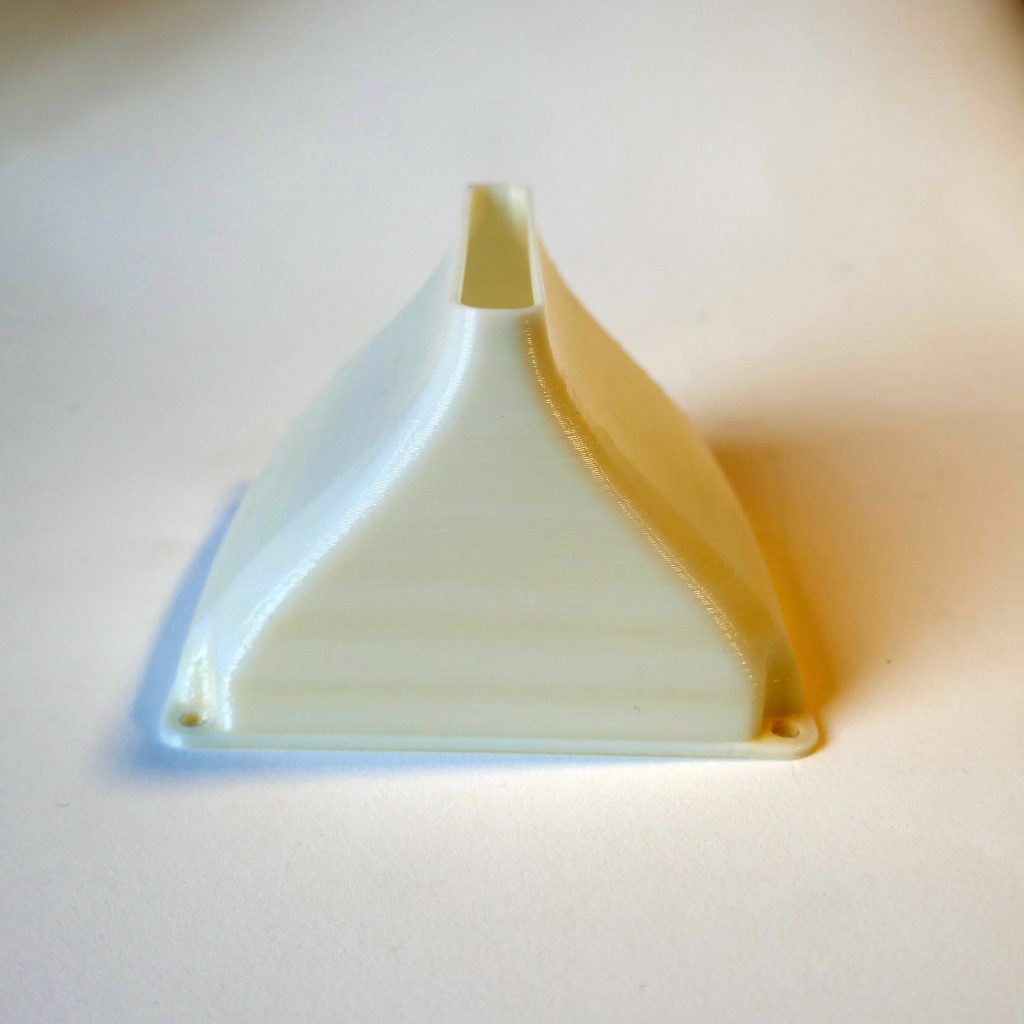

In an attempt to upcycle it, I designed a duct that converts it into a blower, with a narrower opening. The idea behind this project was to use the high air flow and pressure of this very special fan to blow away the dust from electronics, small objects or hard to reach corners. Using a duct to reduce the fan’s output area, I intended to increase the air speed and “focus” the airflow into a smaller region.

The results are not as good as I expected, the flow doesn’t seem significantly stronger at the duct’s output, but still it is able to move a significant amount of dust. Using a small brush combined with the fan, I was able to effectively clean and remove dust. The only downside is that the dust is not removed from the ambient, as a vacuum cleaner would do, just moved around. It is very noisy, but less so than a household vacuum cleaner.

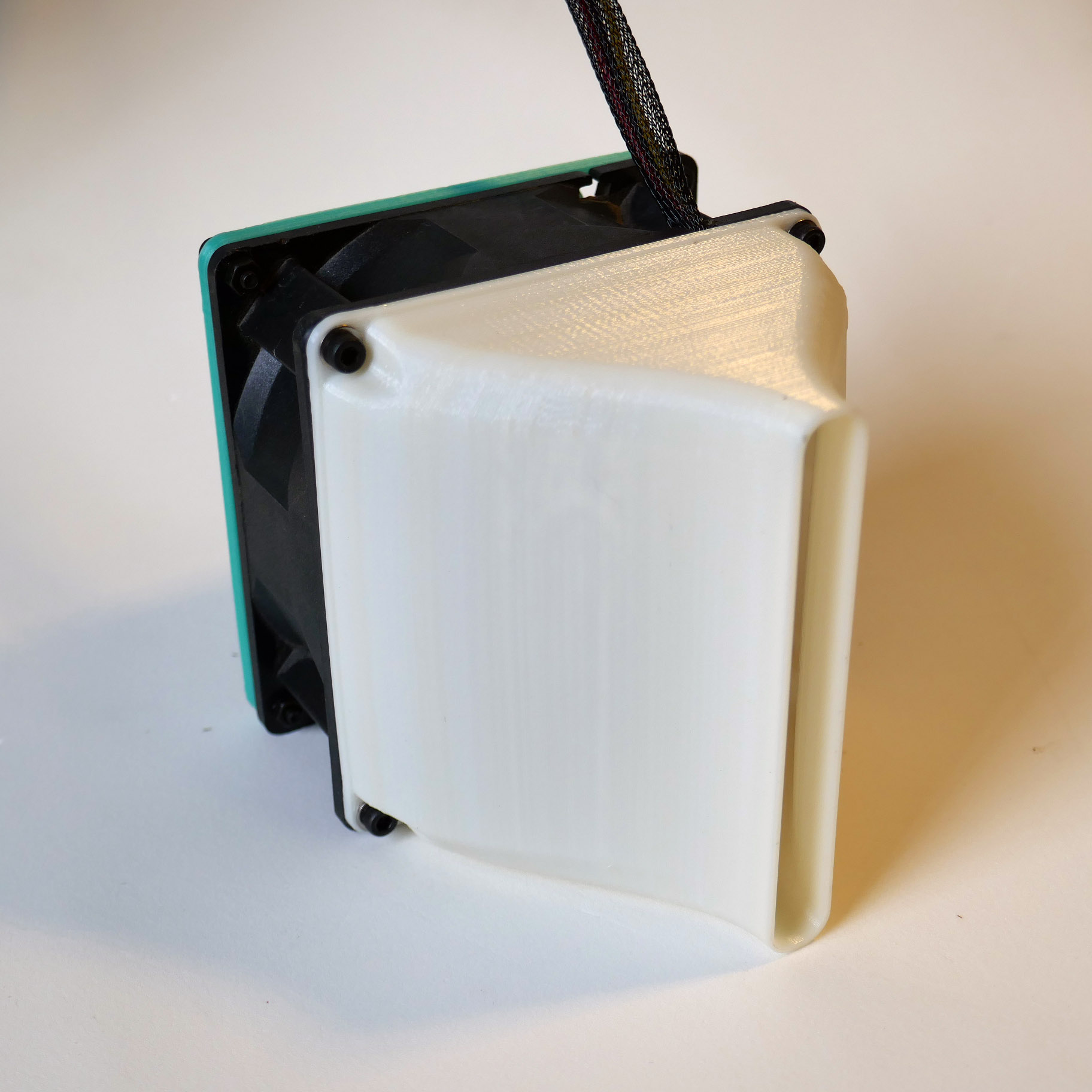

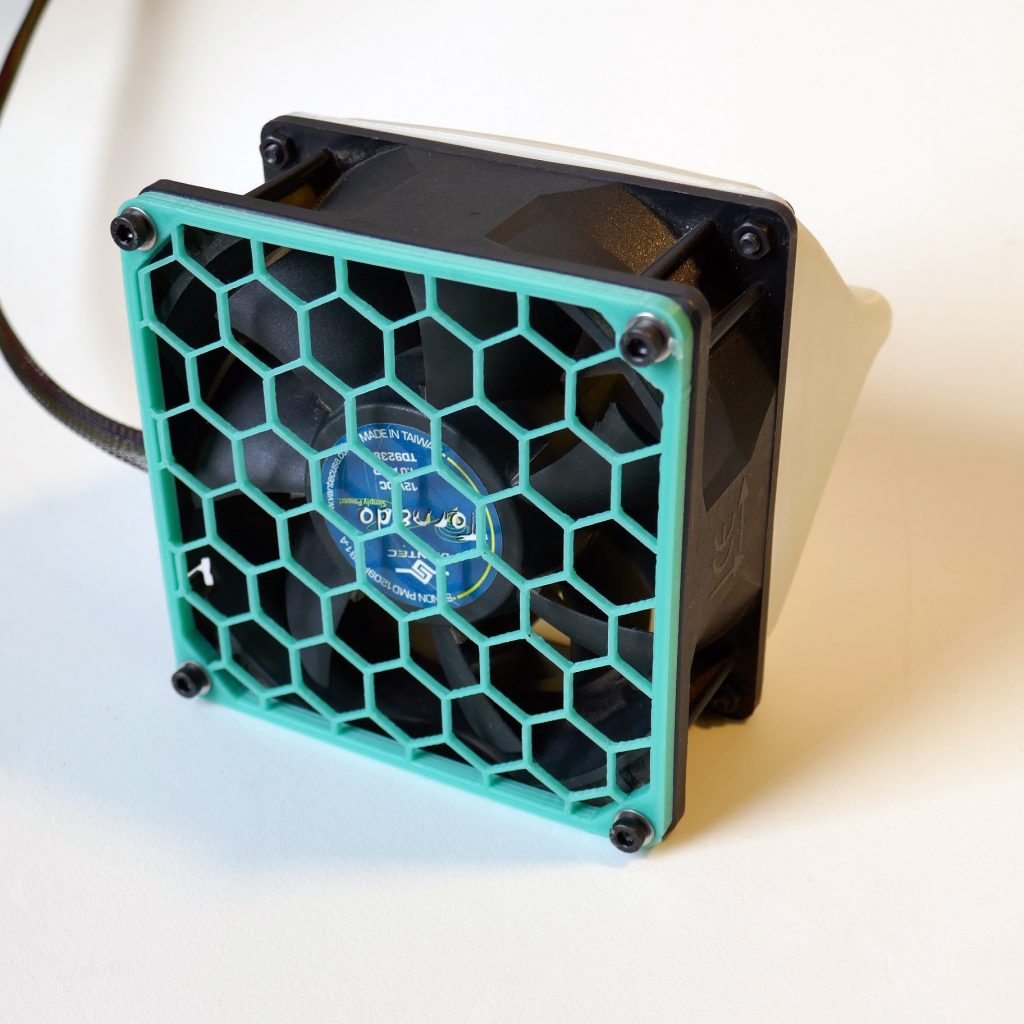

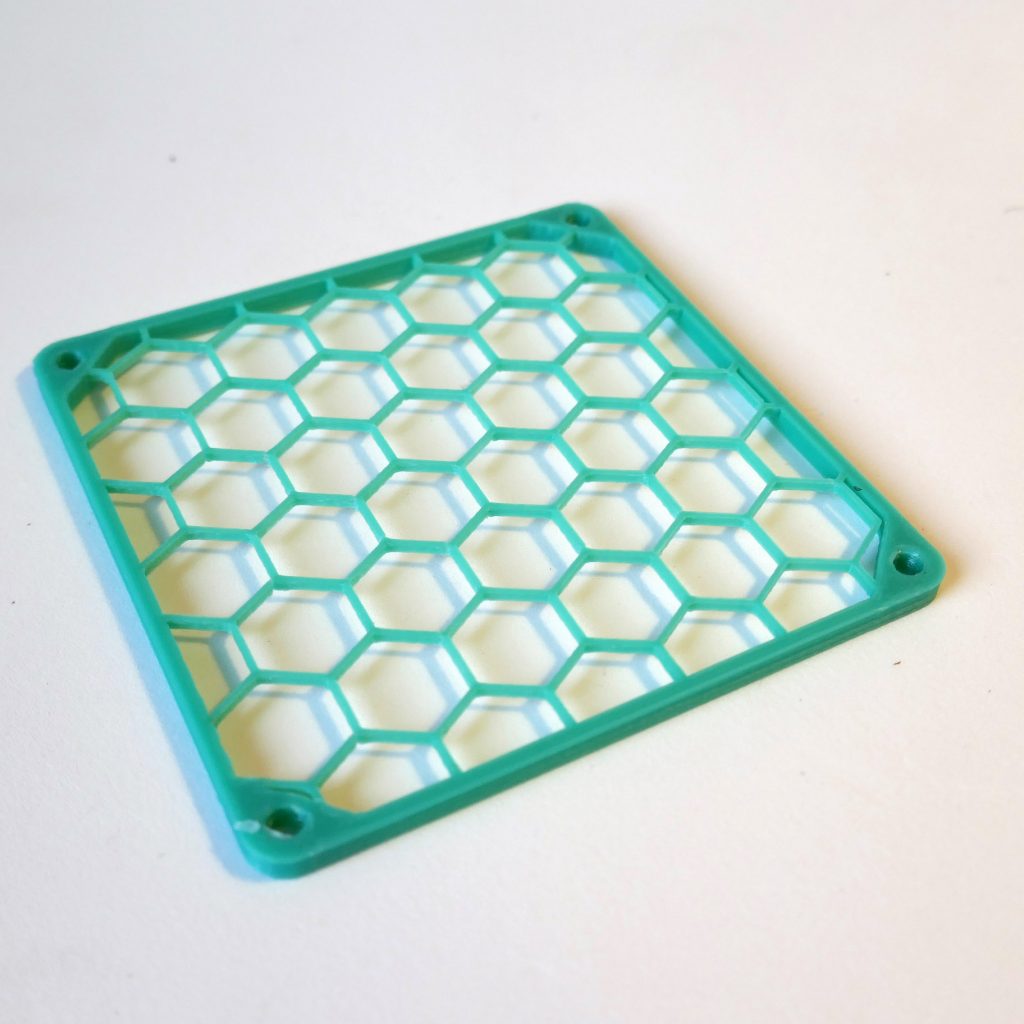

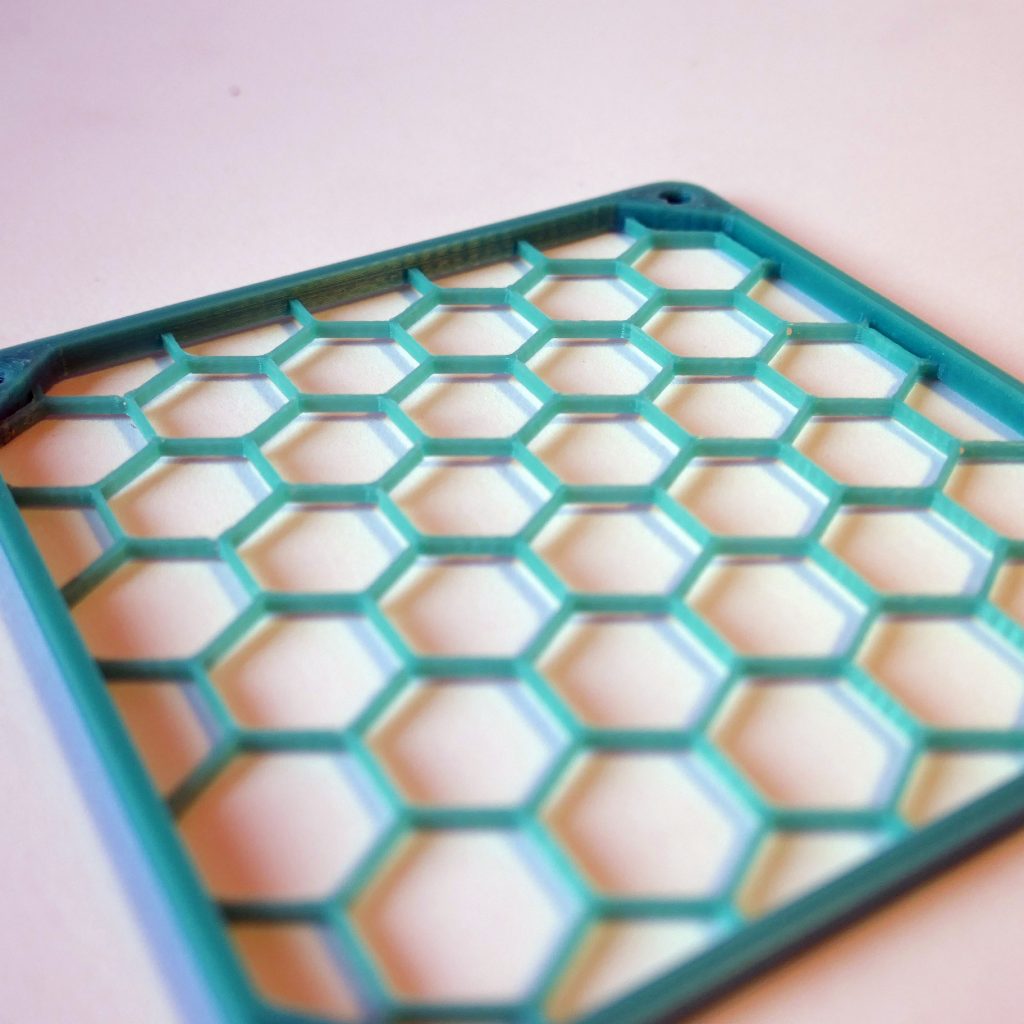

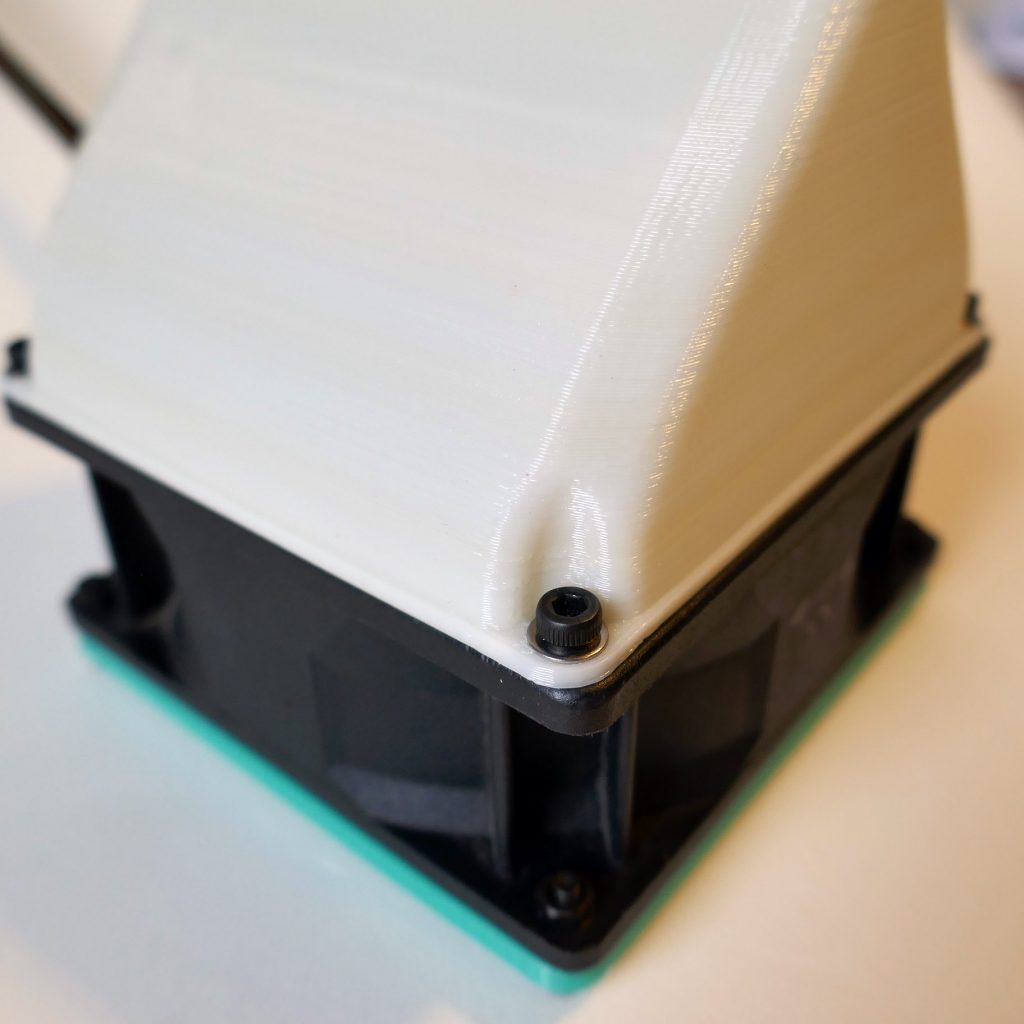

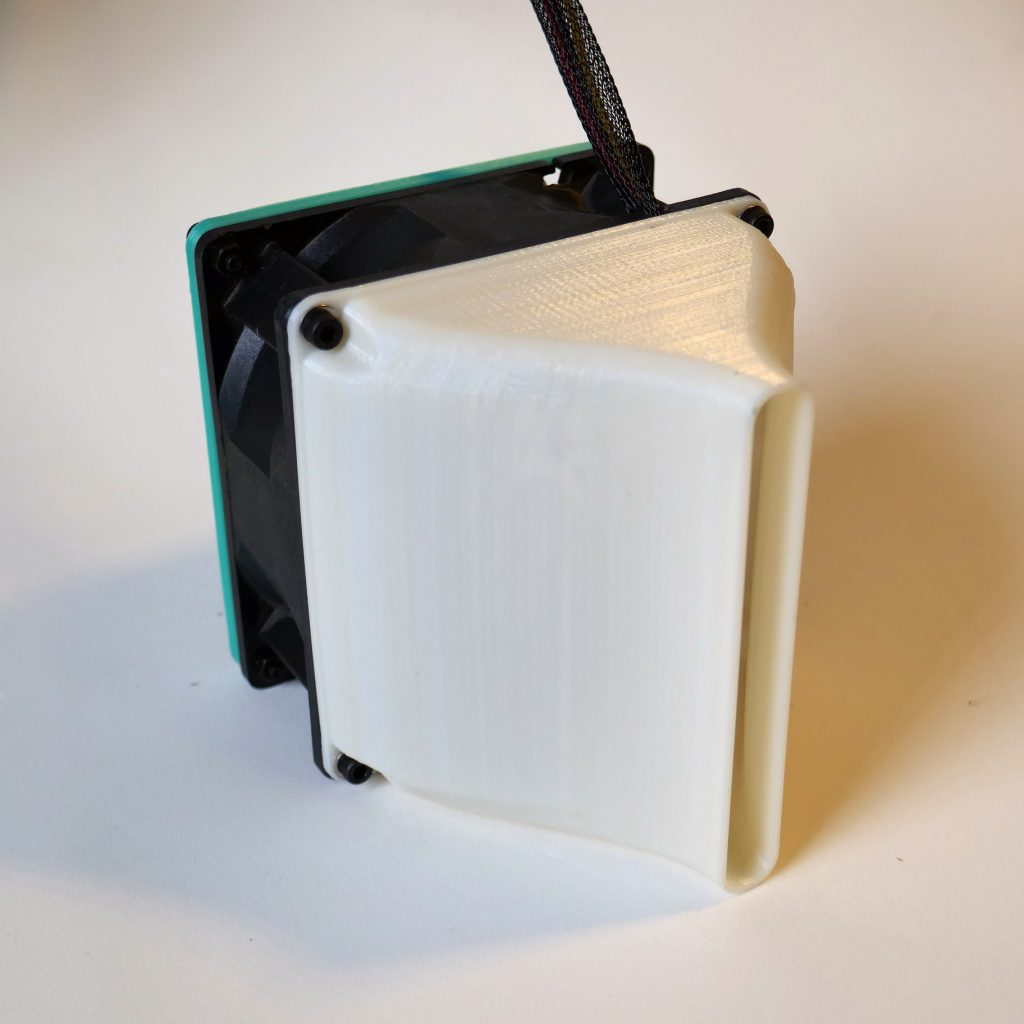

In the gallery below, you can see pictures of the complete assembly: fan, duct and finger guard. The finger guard was printed in green ABS and is essential for safety when using a fan as powerful as this one, as it can cause serious cuts at full speed. The duct was printed in natural ABS without supports. I used M3 screws to attach the 3D-printed components to the fan.

The designs are available at Thingiverse: 92 mm honeycomb fan guard and 92 mm Fan Duct to 10 x 90 mm Output and 60 mm Height

Nowadays, the most commonly used computer fans are 120 mm or 140 mm, operate at low RPM’s (<1500) and are barely noticeable over ambient noise. There are still very powerful fans available, mainly used in industrial applications where noise is less of a concern when compared to cooling performance and reliability, but their usage is not common among PC enthusiasts. Many years ago I got a great deal on 2 industrial 120 mm Sanyo fans, that run at 12 V and 0.4 A. They’re loud, but not obnoxiously so as the Tornado, and were used for a long time in my computer, before I replaced them by quieter ones.

In my office’s window there are mosquito screens and they end up blocking the wind quite significantly. Since the window is not wide enough for me to put a common household fan, I designed two parts that let me use the 120 mm instead.

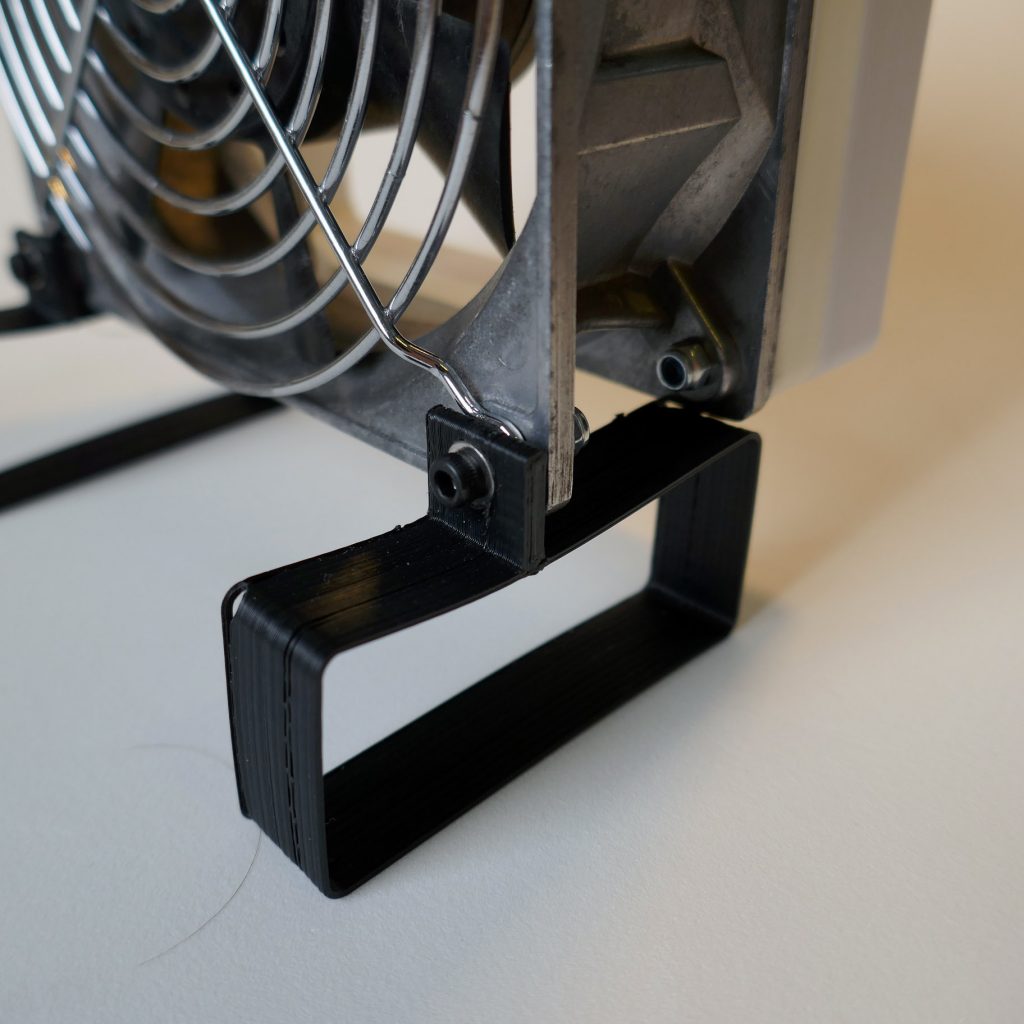

The first one was printed in black ABS, it is a support that may be attached to the fan, raising its height and increasing the stability of the assembly. The support was designed to use the minimum possible amount of material (2.7 g each), while also providing some vibration dampening. Its walls are thin, at just 1.0 mm, making the supports flexible, which might help isolate the vibration. These supports were needed to clear the window frame, when the fan is positioned behind the screen.

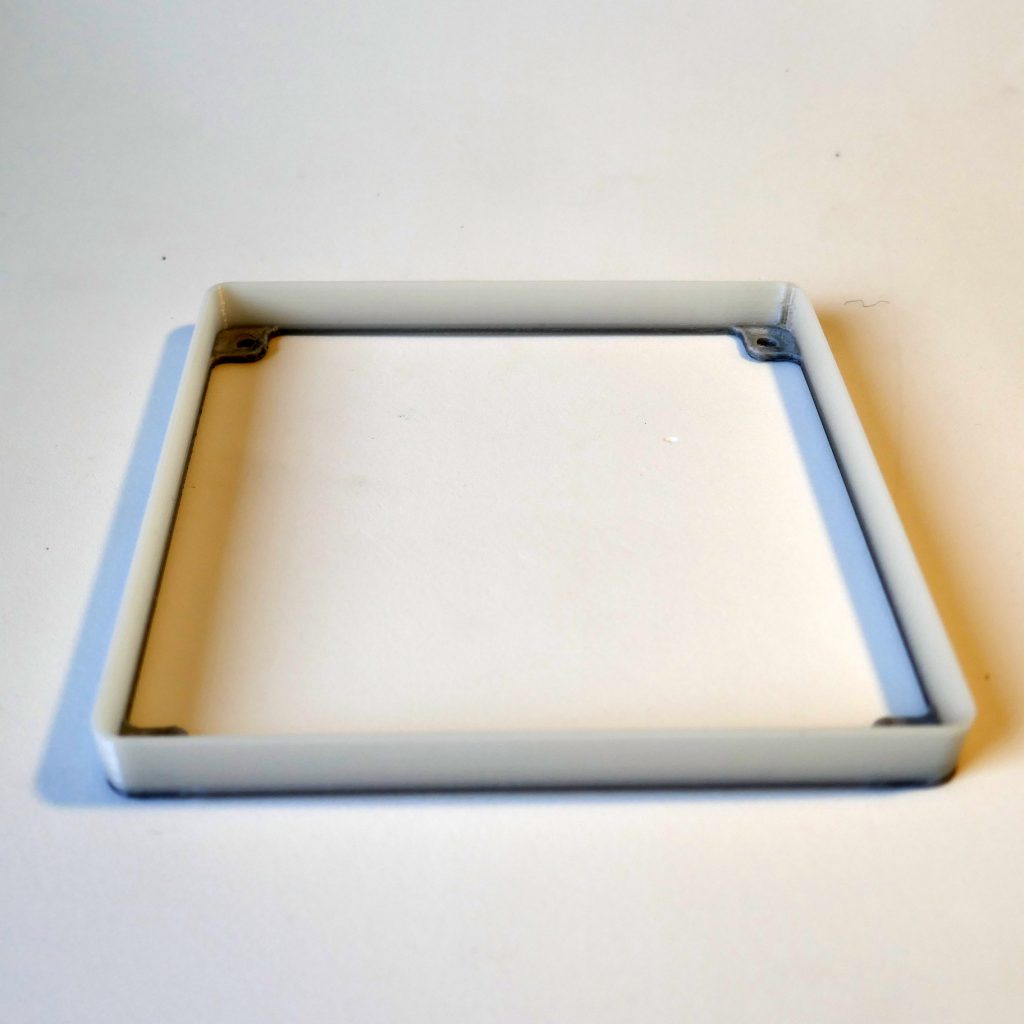

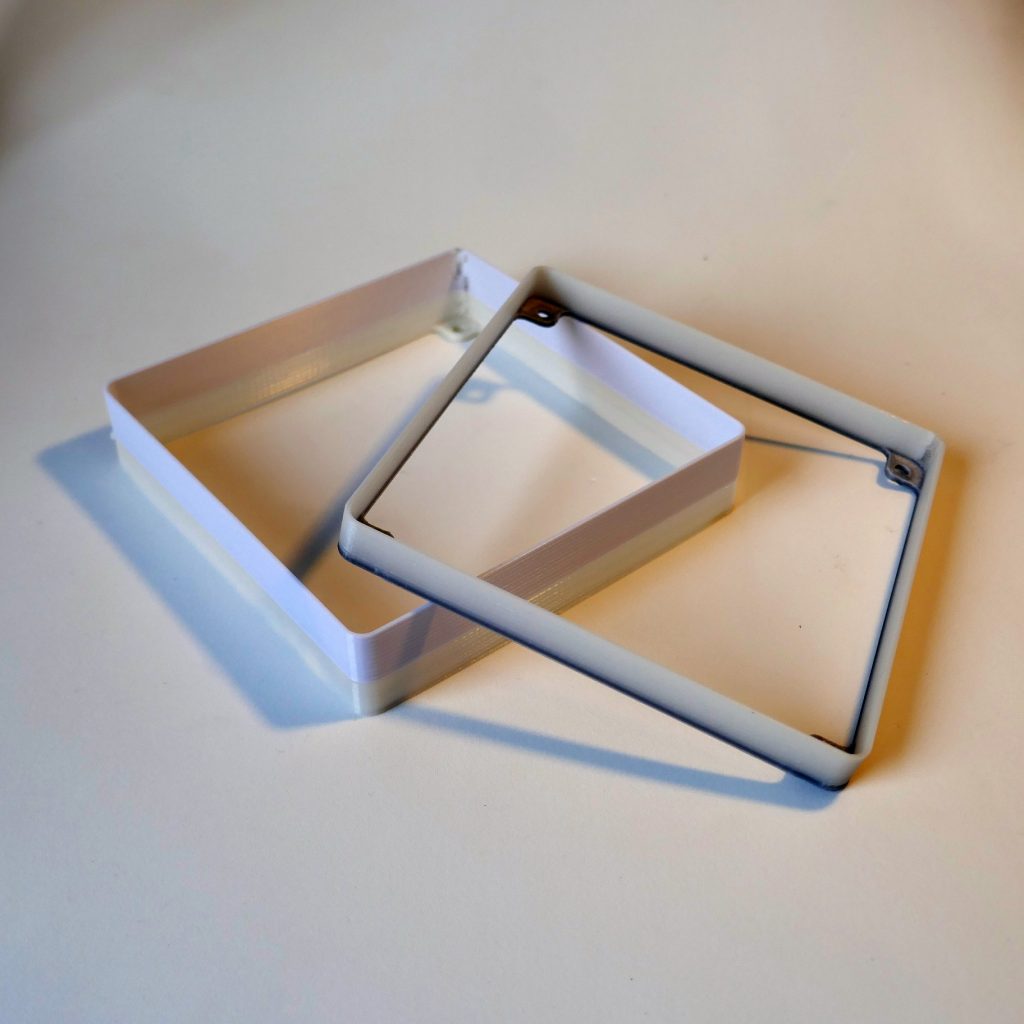

The second design is a shroud that extends the fan’s output so that all the air flow goes through the mosquito screen. This was necessary, otherwise a very insignificant amount of air would go through the screen, with most of the air just recirculating around the fan. In the pictures two shrouds are shown, one longer than the other, allowing me to position the fan closer or further away from the screen. The shrouds were printed in two colors just because I wanted to finish some filament rolls.

These designs are available at Thingiverse: Minimalist Fan Support Feet and 120 mm Short Fan Shroud